Alcohol Test for Assessing the Raw Milk Quality

The alcohol test is used on fresh milk to indicate whether it will coagulate on thermal processing. This test is especially important for the manufacture of UHT milk, evaporated milk and milk powders. This test is more sensitive than Clot-on Boiling (COB) test. It is based on tendency of milk protein to get unstable as a result of disturbance in the mineral balance of milk.

Milk with high developed acidity, or having calcium and magnesium compounds in greater than normal amounts, will coagulate when alcohol is added. Increased levels of albumen (colostrum milk) and salt concentrates (mastitis) may also results in a positive test.

In dairy industries, normally three different concentrations of ethanol solution are used for the test, depending upon the further use of milk. These are 68% v/v, 65% v/v and 60% v/v. Milk which passes 68% ethanol test is considered as that of superior quality. For manufacturing UHT milk and milk powders, the raw milk should pass 68% ethanol test. Dairies generally consider 60% ethanol test negative raw milk for manufacturing pasteurized polypack milk as it does not have to undergo rigorous heat treatment as in case of UHT milk. The milk which do not even pass 60% ethanol test is rejected at the processing units.

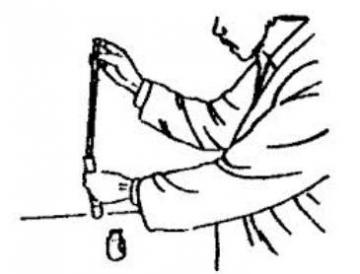

Procedure: For routine testing, 5 ml milk is mixed with 5 ml of ethanol solution. If the tested milk is of good quality, there will be no coagulation, clotting or precipitation. Presence of flakes or clots indicates poor quality milk.

References:

1. http://www.fao.org/ag/againfo/resources/documents/mpguide/mpguide2.htm

2. IS : 1479 ( Part 1 ) – 1960 (Reaffirmed 2003)

100 public://rawmilk.jpg