Production and Processing of Bovine Semen and Quality Control – Current status and future Challenges

C P Devanand Productivity Enhancement Group NDDB Dairy Services

New Delhi

India has one of the largest networks of AI centres in the world with about 95000 centres carrying on an average about 650 AI in a year. Semen production in the country has increased from 22 million straws (1999-2000) to 81 million straws (2012- 2013) and the number of inseminations from 20 million to 62 million (22 million animals under AI coverage). The overall conception rate has also increased from 20% to 35%.

The success of any large scale AI program depends largely on the quality of the semen used for breeding. Sustaining quality in a system producing biological products, such as frozen semen, requires high levels of synergy between the producer and the end user. Unlike the dairy advance countries, the field AI delivery systems in our country are still being developed and hence a combination of factors viz. cold chain management of semen doses in the field, skill of the AI technicians in handling of semen doses etc could affect quality of the product once it leaves the production station. Considering this fact, it is all the more essential that semen stations put in place robust protocols and processing systems to ensure production of a quality product consistently.

In order to ensure the quality of frozen semen produced, the Minimum Standard Protocol (MSP) for frozen semen production was formulated and implemented at all semen stations in the country. A Central Monitoring Unit (CMU) was also constituted for evaluation, once in two years, of implementation of Minimum Standard Protocol for semen production by the semen stations in the country. To meet the requirement of adoption of the MSP by the semen stations, funding has been provided by Government of India and considerable improvements have been made in the semen station infrastructure particularly in the semen stations graded ‘A’ and ‘B’.

Challenges

While there has been a striking improvement in the infrastructure and quality systems available at the semen stations graded A and B, there has been no developments with regard to the minimum prescribed tests & frequency of tests for the product quality post formulation of the MSP. The important components for a quality control program are: replication of an acceptable test, minimizing error due to the test procedure and detecting meaningful biologically important differences among semen samples. The three critical tests prescribed in the MSP for semen quality are- the sperm concentration in the semen dose, post-thaw motility and the microbial quality. Of these except for sperm concentration the other two tests have issues of repeatability & reproducibility. The sampling plans for product acceptance to ensure that the semen doses released from the semen station are well within the stipulated average outgoing quality limits also need to be specified.

Considerable investment both in terms of money & time have been made by the existing semen stations for carrying out these tests in the prescribed frequency. It is probably time that the stations raise the bar and move over the minimum standards prescribed for the semen production and focus on a limited number of tests that predict fertility with greater accuracy. This can be possible only if studies to correlate the findings of the laboratory tests with the ultimate field data on fertility are taken up. The insights from these results will provide the impetus to optimise the different types & the frequency of QC tests to be carried out in frozen semen. In contrast, the semen stations in dairy advance countries have efficient data management systems to monitor the field programmes which provide reliable feedback on various technical performance indicators. The developed nations have therefore been able to evolve a leaner operation, wherein the sperm load in the semen dose is comparatively lesser than in the Indian scenario where considerable cushion needs to be provided to compensate for the handling of the semen doses post production. This is one of the reason that innovative technologies like sexed semen could not be adopted on a large scale in India. It is high time that sperm load in semen doses be made flexible to allow lower loads for high genetic merit bulls with proven high fertility and higher loads for comparatively lower fertility bulls. This would lead to better benefits to the dairy farmers and also maximising the use of high genetic merit bulls.

Another area which requires attention is the cost, standardization and capacity utilization of the semen processing equipment used by the semen stations in the country. Most of the semen stations in the country have a heterogeneous breed mix, however the breed wise variations in calibration/ standardization of the equipment have not been fully addressed. The studies on process capability index for most of the equipment routinely used in the semen station has not been carried out and also there are no estimates for the product variability in the currently recommended semen processing protocol. It is well known that there exists considerable variation not only between breeds but also within breed in their response to the frozen semen processing techniques and the uniform processing protocol for semen processing leads to considerable rejection in post-thaw discards.

The currently available equipment do not permit breed level or bull level customization of configuration with minimal lead time. Also there are no equipment manufacturers catering to the custom needs of different semen stations based on their own scale of operation. Due to this each and every semen station has to end up making huge capital investments for the equipment and the capacity utilization of the build-up infrastructure at most of the semen stations remains an area of concern.

Many of the problems related to cryo preservation can be resolved through synergy between the semen stations and the research organizations in the country so that the challenges faced by the semen stations are adequately addressed and innovations of value in the field of cryopreservation are adopted. The semen stations in the country have over the year huge data relating to frozen semen processing in different breeds which should be shared with agencies pioneering research in the frozen semen technology so that a comprehensive assessment of issues and challenges faced could be addressed.

Policy interventions which facilitate easy adoption of recent advances in the semen processing techniques from the developed nations could be a fillip to the individual efforts of the semen stations in the country. A national level forum representing the semen stations could bring out these issues to the notice of the policy makers so that the country does not miss the next innovation jump in the field of frozen semen technology.

Our Experience

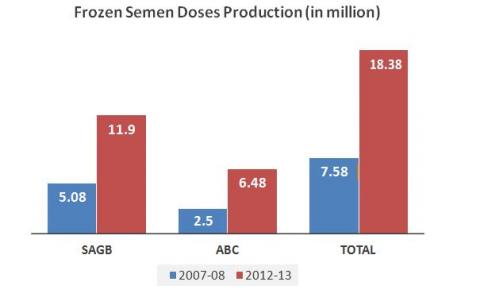

At Sabaramati Ashram Gaushala, Bidaj (SAGB) and Animal Breeding Centre (ABC, Salon), the semen production has increased from 5 and 2.5 million respectively inn2008 to a total of about 18 million semen doses in 2012-13.

Capacity utilization was ensured by processing semen in two shifts which was introduced in the year 2008. The heavy load of activity in the semen lab was supported by tighter controls and facility up gradation to avoid the pitfalls of quality deterioration. The frequency of the prescribed quality tests, the microbial load in

particular was also intensified to timely detect lapses in the semen processing hygiene and sanitation measures. Further, in-order to avoid the subjectivity judgement in the pre-dispatch quality check for post thaw motility, Computer Assisted Semen Analyser (CASA) was introduced in the year 2011. All the clients are now being provided a CD of the CASA evaluation video as a gesture for ensuring the confidence in the QC check carried out at SAGB and ABC.

As part of the standardization of the QC testing procedures, joint workshops for the SAGB and ABC staff are organised to improve the repeatability and reproducibility of the test results. A well-defined acceptance sampling plan has empowered the technical staff in decisions pertaining to the QC reject. Sensitization of the technical staff on the cost aspects of the semen production and overall financial performance of the semen station is also an important of the training and has helped to reduce the rejections in the system.

A customized Information System helps to automatically capture finer details of semen collection and processing like- Semen Collector, Collection crate, Bull handlers, diluent quantity, time & temperature at each stage of processing etc and provides a valuable database for improving the semen processing system.

Conclusion

Artificial Insemination has been long used as a tool for the rapid genetic improvement of the bovine population in the country. In the current scenario, where in the country is in process of abridging the demand supply gap for milk, increased adoption of AI is of utmost importance to improve the productivity of the dairy animals in the country.

Breeding operations in the country beset with operational constraints, it is necessary that semen production stations equip themselves with the technology to evaluate and process semen so that there is minimum deterioration in its inherent quality to fertilize. Production of a quality product involves cost and consumes financial and human resources. Therefore time has come to design more efficient and effective structures that focus on adding value to the product without increasing costs.

Considering the above facts, each semen production center must strive to develop and continually revalidate semen collection and processing protocols using acceptable viability criteria that are consistent with recommendations. In house quality audit and effective implementation of quality management systems would lead to continual improvement of product and service leading to enhanced customer satisfaction. This would ensure that a quality product is consistently produced and delivered through proper design and efforts.

Data Source: Annual Report’ 2013-14; DADF, Ministry of Agriculture, GoI

Dr. C. P. Devanand

Education:

Received his B.V.Sc and M.V.Sc., from Kerala Agricultural University. Has completed MBA in Finance.

Current Professional Engagement:

Head, Productivity Enhancement Group, NDDB Dairy services, New Delhi.

Professional Experiences:

Joined the Kerala Livestock Development Board, a premier organization in India providing inputs for animal breeding activities, discharged duties at various farm units of the Board including as head of units. In April 2005, he joined Sabarmati Ashram Gaushala and was instrumental in implementation of Productivity Enhancement activities, expansion of the business network and General Administration.

In 2013, joined NDDB Dairy Services, where he provides technical and managerial support to Sabarmati Ashram Gaushala, Bidaj and Animal Breeding Centre, Salon, two of the largest semen production stations in the country. To meet the requirement of semen doses envisaged in NDP I, NDDB Dairy Services is establishing two new semen stations in the states of Tamil Nadu and Maharashtra each with a capacity to produce 10 million semen doses.

Contact: devanandcp@rediffmail.com