1.2.3 Quality control of finished product

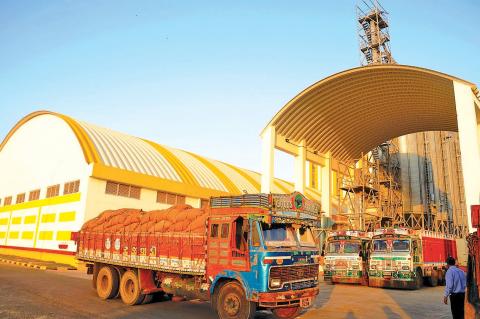

All measures which are concerned with the quality control of finished product should be carefully reviewed to maintain high standards. The finished product should be examined for colour, texture, pellet size, strength, aroma, palatability and chemical composition before delivery (Fig. 1.3). Periodical evaluation is also necessary to examine the health of the animals and effect of feed on their productivity through field survey. There may be seasonal variations in the standards or the basis of availability of basal diet and its quality and quantity during different seasons. The product manufactured should be analyzed and compared with set standards. The finished product lot should be cleared for marketing only after the approval of the animal nutrition officer. Besides quality, the net weight, proper packaging and safe transport to the retail sale outlets may also be ensured. It is of utmost importance for the production unit to take adequate care in compounding of the feed as per formula prescribed by the animal nutrition officer.

The wide variation in the chemical composition of the ingredients is obtained. This is the main constraint with which the nutritionists have to formulate the ration to maintain the quality of the feed at affordable costs. Choosing the best quality raw materials continuously throughout the year is nearly impossible. Further, nutritionists are not in a position to reject materials if there is variation in the specification since the availability is constant or lower and the demand is increasing. Therefore, fixing the cost of ingredients on the basis of nutrient content and using them in the formulation with certain additives is the most practical option possible.

Fig. 1.3 Finished products should be tested before delivery